This is the first post in a blog series documenting my method of construction for an entire set of custom kitchen cabinets. This series is not intended to be a full how-to tutorial, but rather to show the sequence of steps using photos and commentary. You can find all the posts in the series here. Please comment below or send follow-up questions to jonathan@jmoncton.com.

Today I made my major raw materials run. My truck is loaded up with 14 sheets of 18mm (3/4”) plywood, 8 sheets of 6mm (1/4”) plywood, and 200 board feet of Brazilian mahogany.

This is right at the limit of the 1600 lb payload capacity, but the truck handled just fine on the hour trip back from Exotic Lumber in Annapolis to my shop in NW Washington, DC.

The plywood rests on 3 pieces of pallet material and the whole bundle is pulled tight to the bed with heavy duty ratchet straps.

For my method of frameless cabinetmaking (more on this term in later posts) I use only “veneer core” plywood to construct the boxes. That means that each layer of the plywood is the same wood material with a thick outer layer that can be machined and sanded.

Most “cabinet-grade” plywood has a very thin (typically 1/42 inch) outer veneer that will disappear almost instantly upon contact with sandpaper. The inner layers are usually poplar, but often are just some soft mystery wood or other material with comparably little strength.

The two veneer core plywoods that I use are Baltic Birch, which is inexpensive and readily available, and Okoume, which is more expensive and available only through select marine-oriented lumber facilities.

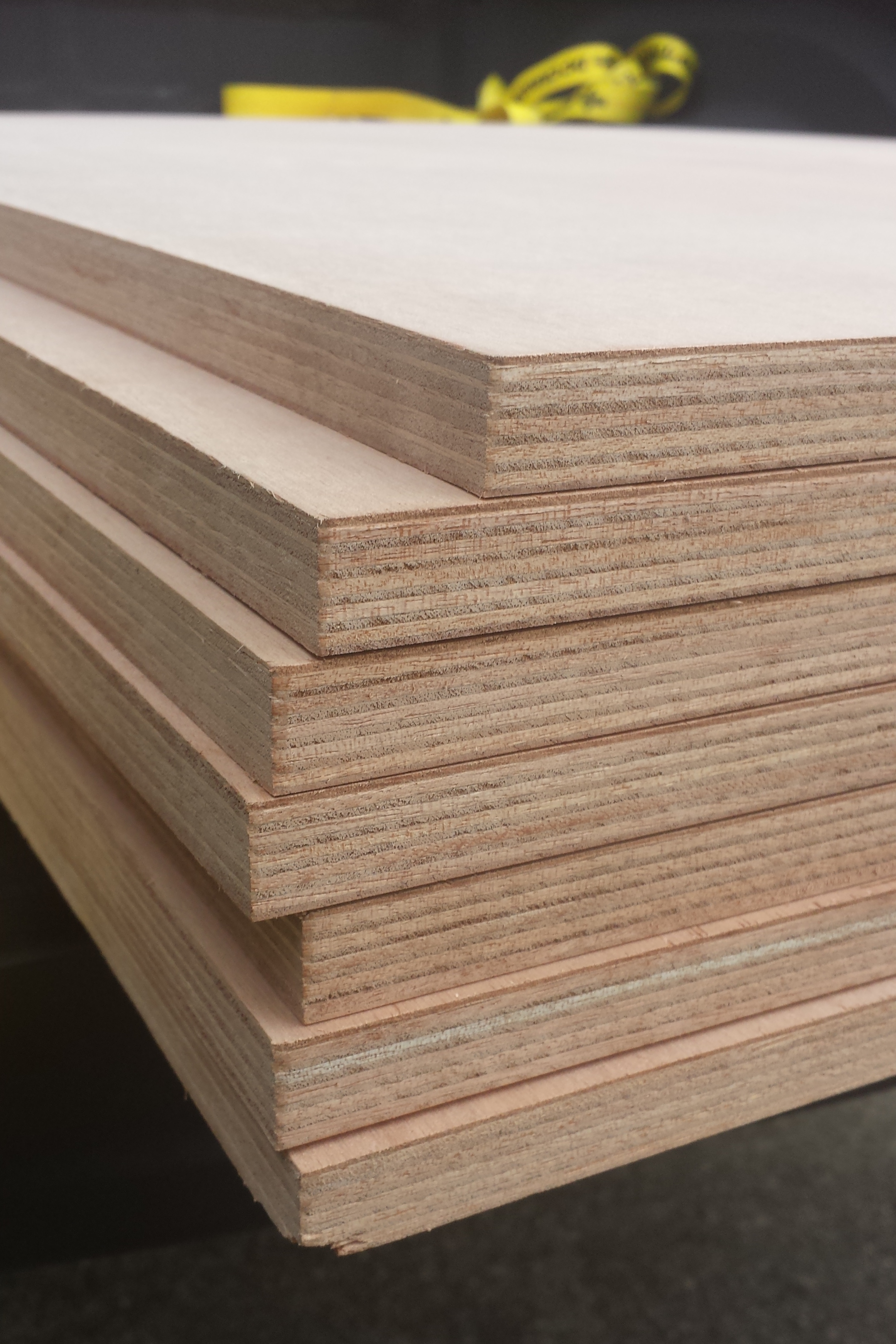

Below is a closeup of the stack of Okoume plywood. Note the thick (nearly 1/16”) outer veneer and crosshatched inner layers of wood.

The mahogany hardwood will be used as solid wood edge banding for the plywood, for the door frames and drawer fronts, and for any necessary trim pieces in the kitchen.

The mahogany now occupies the lowest level of my new welded steel lumber rack. With five levels for wood storage, it can hold about 1000 board feet of lumber with the top rack reserved for steel stock.

Up next I will break down the plywood into cabinet components and make a batch of solid wood edge banding.

Thanks for reading. You can find the next post in the series here.